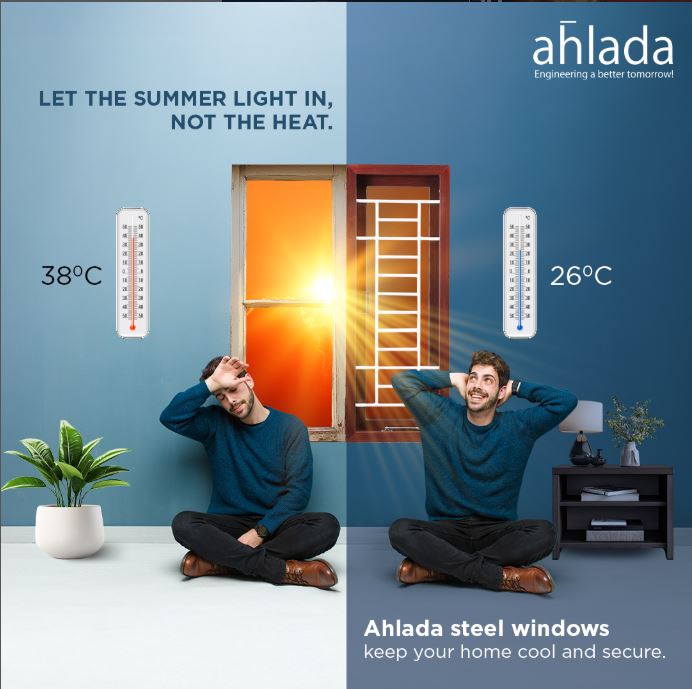

From hot and harsh to cool and cozy, Ahlada steel windows and doors help maintain a comfortable indoor temperature by blocking excess heat while still allowing ample natural light and ventilation. Their insulated designs also improve energy efficiency, which can reduce the load on fans and air-conditioners during peak summer.

How Ahlada windows keep rooms cool

Ahlada residential steel windows are made from high‑grade galvanized steel with specialized coatings that resist heat, warping, and corrosion, even in intense sun. These frames are engineered to reduce heat transfer from the outside, helping interiors stay noticeably cooler through the day.

The window designs are optimized to let in abundant daylight and cross‑ventilation, so you enjoy bright, airy rooms without the harsh glare and heat build‑up of traditional openings. By limiting direct heat gain yet supporting airflow, they create a more stable and pleasant indoor climate.

Role of insulated steel doors

Ahlada steel doors use insulated cores, such as honeycomb kraft paper, which act as natural thermal barriers between indoor and outdoor areas. This insulation helps prevent hot air and external temperature spikes from quickly affecting your living spaces, making homes feel cooler in summer and cozier in winter.

Modern sealing and weatherstripping around these doors further cut down on drafts and unwanted heat exchange, boosting overall comfort and lowering energy consumption.

Comfort, savings, and durability

Because Ahlada’s insulated steel windows and doors reduce reliance on artificial cooling, homeowners can benefit from lower electricity bills and a more eco‑friendly home. At the same time, galvanized steel construction and anti‑corrosive finishes deliver long‑term durability with minimal maintenance, even in harsh, high‑temperature climates.

For modern Indian homes seeking both thermal comfort and security, combining Ahlada steel windows with matching steel doors creates a cohesive envelope that keeps interiors cool, bright, and safe throughout the year.